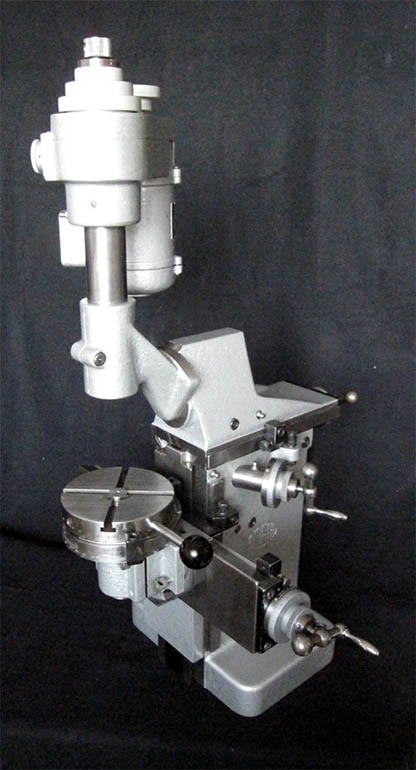

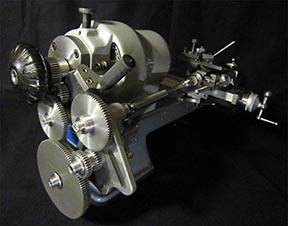

Now I have three machines: Schaublin 70, Aciera F1 and M1 Hauser. This choice is not random. These three machines are equipped with collets W12 and B8.

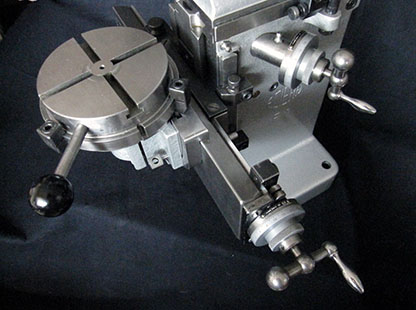

Aciera and Hauser has identical aperture for equipment - 35 mm. So all of the accessories can be changed with each other.

All seats are equipped with lubrication nipples and are served with a special lubricant pump. The machine must be regularly lubricated.

ONLY LIQUID OIL (sewing machine oil) USE!

I already revise a lot of machines and I must say that by the machines, oiled with fuel oil, all the channels are clogged. And sometimes the working knots and bearings are irretrievably damaged, and replacing them is worth a lot of work.

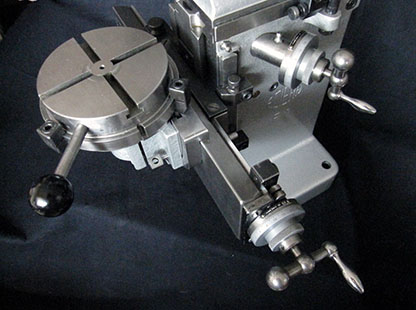

Technical data Aciera F1

Work areas:

- Longitudinal travel of table 100 mm

- Vertical travel of table 150 mm

- Cross travel of the spindle head 75 mm

- Reading on dividing drums 0.01 mm

Spindle milling:

- Type W-12

- Spindel seat for collet shanks Ø 12 mm

- Clamping area of collet 0 - 10 mm

- Spindle speed 125-250-500-1000-2000-4000 rev/min

(with frequency converter freely regulate between 0-4000 rev/min)

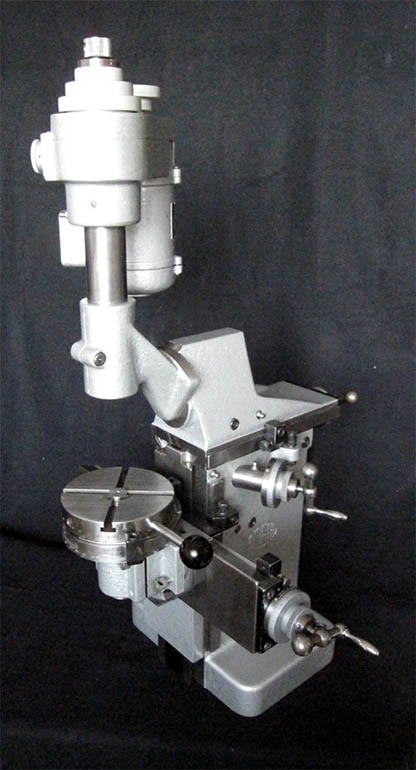

Weights and Dimensions:

- Machine without stand:

- Length 600 mm

- Width 500 mm

- Height 570 mm

- Weight approx. 55 kg