Type I

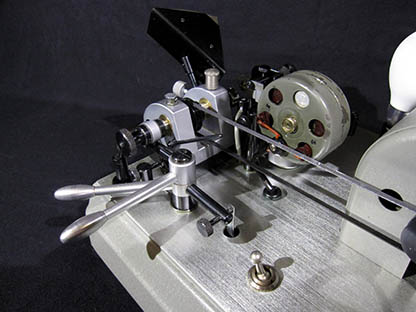

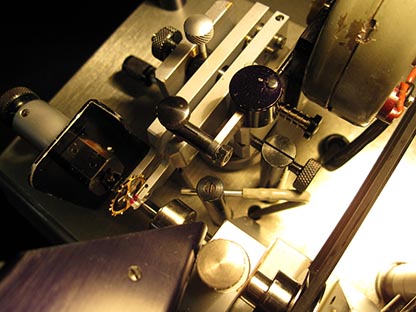

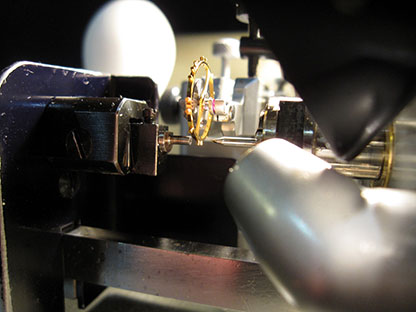

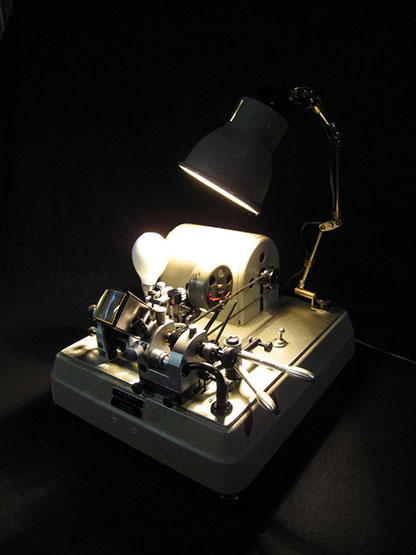

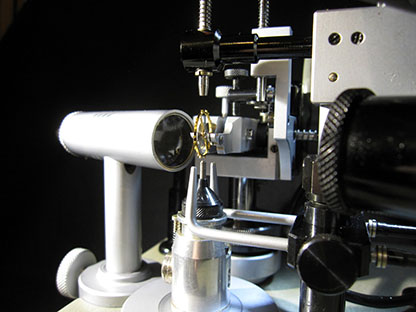

The manufactured balance is placed on the measuring lever. By pressing the hand pumpas, air is supplied to the movable nozzle and leads to a balance rotation. When the balance comes to a state of rest, unbalance becomes visible and the heavier part under gravity displace down.

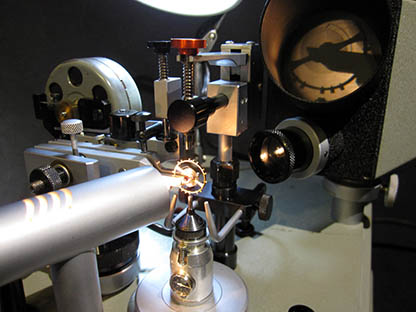

If you press the lever, the vibrator unit turns on and this improves the measurement procedure.

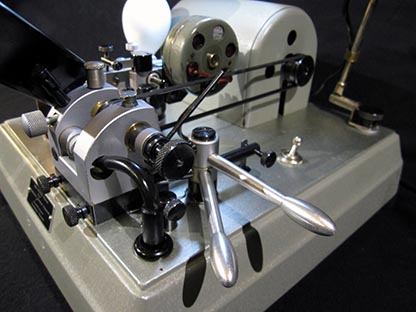

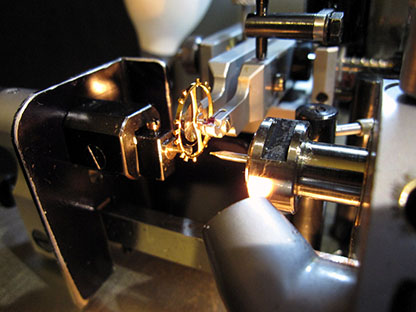

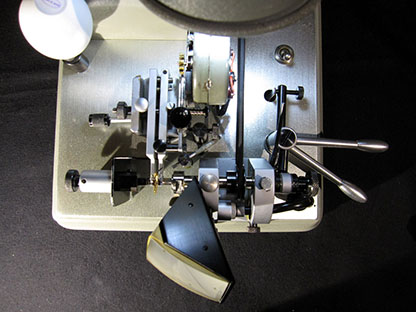

The next step is to determine the bolt to be lightened. After that, a little material is drilled from the bolt cap. The apparatus is equipped by a drill spindle with a collet, into which a drill with a diameter of 0.4 mm is clamped. The diameter of the drill is limited by a brooch. The depth of drilling is shown on the measuring clock a scale. In this way, an accurate balancing of the balance is possible.

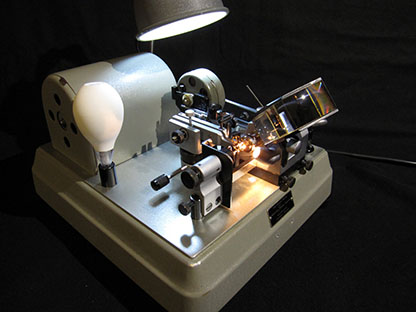

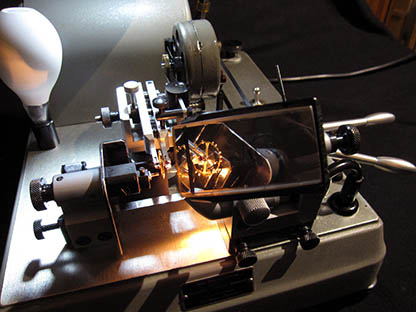

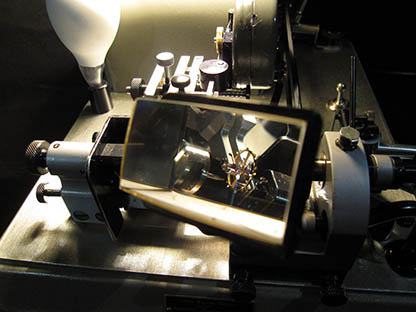

The setting and the adjustment of the apparatus is very diverse. For example, you can precisely adjust the position of the drill to the arrow of the measuring device. All important parts are equipped with the ball bearings or the bearings with rubies, thereby minimizing the effect of gravity on the indicator. Using a beam of light, the black silhouette of the balance is projected onto a small screen. This is an interesting addition to the clock loupe, which is always at hand.

How this device functions, I found by experimenting myself.

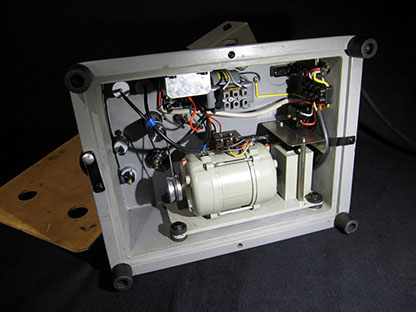

Before the work the device must be scrupulously leveled. This is done with a help the legs, using the level, since there is no built-in one.

On the devices manufactured later, the places with wear and tear were replaced with rubies.

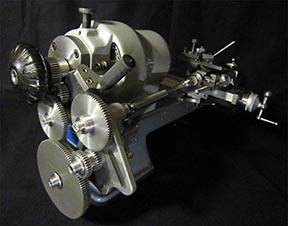

The parts of the device are made of aluminum and brass. These metals have not magnetism, which hinders for the measurement process.