In 1898 Henry Hauser founded a workshop to manufacture machines for watchmaker and immediately noticed the potential for mechanization in the watch industry.

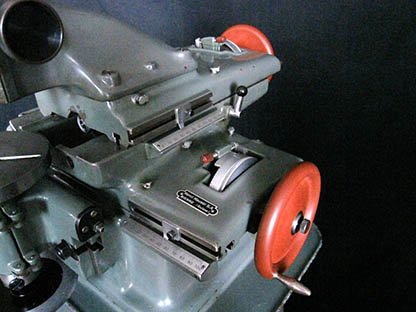

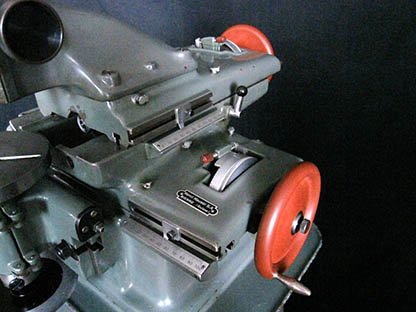

Machine Hauser M1 60 -70 years of the last century has proven Swiss quality, it is used as a coordinate machine, measuring microscope and boring machine.

The construction is very stable. Small milling operations can be performed on it.

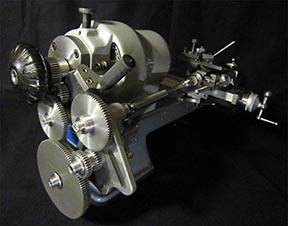

Hauser M1 is equipped with a circular table, a centering microscope with 35x magnification, a punch and boring spindle.

Boring spindle with collets B8. Despite the compact device, this machine offers accuracy up to 0.001 mm.

Technical data Hauser Type M1:

Work areas:

- Longitudinal travel (X-axis) 100 mm

- Longitudinal travel (Y-axis) 100 mm

- Lifting (Z-axis) 40 mm

- Distance between the table and the spindle 90 mm

Spindle:

- Max. drilling capacity in steel Ø 4 mm

- Max. drilling in cast iron Ø 5 mm

- Lifting the drill spindle (Z-axis) 40 mm

- Max. reaming Ø 12 mm

- Spindel seat for collet shanks B-8

- Clamp of collet Ø 8 mm

Spindle speed:

- from 250 rev/min to 2700 rev/min

Weights and Dimensions:

- Length 600 mm

- Width 600 mm

- Height 140 mm

- Weight approx. 120 kg

Equipment:

- Circular table Ø 135 mm

- 35x centering microscope

- Punch