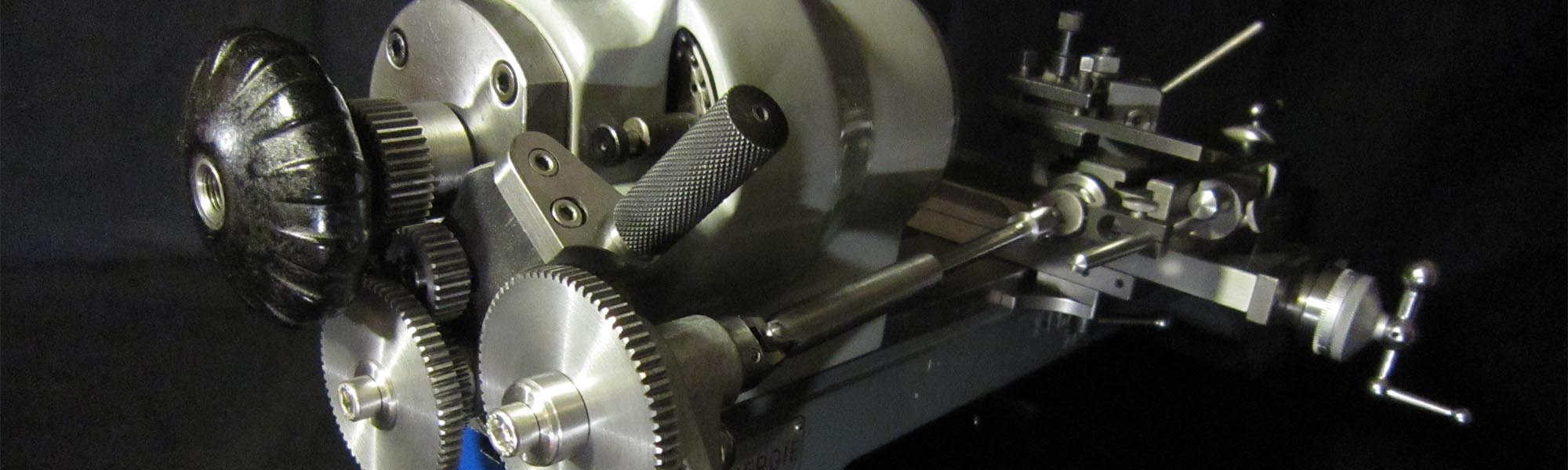

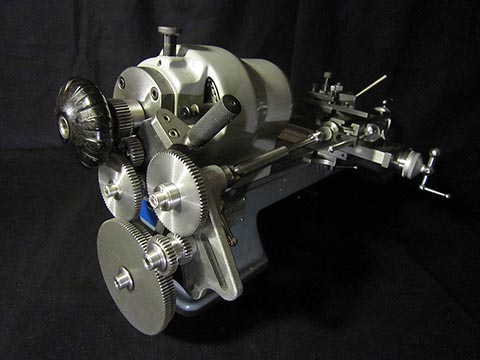

This precision lathe is a classic in watch manufacturing. It features numerous accessories that make its use extremely flexible and versatile. Since its market introduction, the Schaublin 70 has remained virtually unchanged, which speaks to the perfection of its design and its practicality.

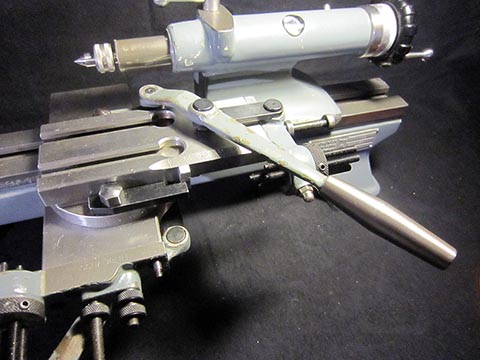

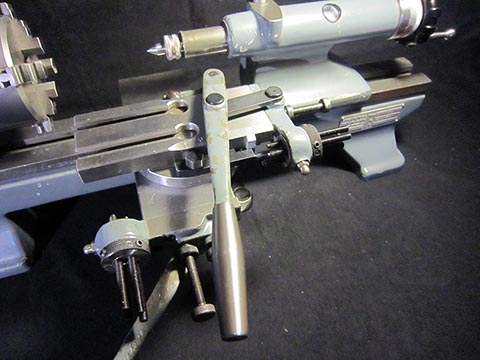

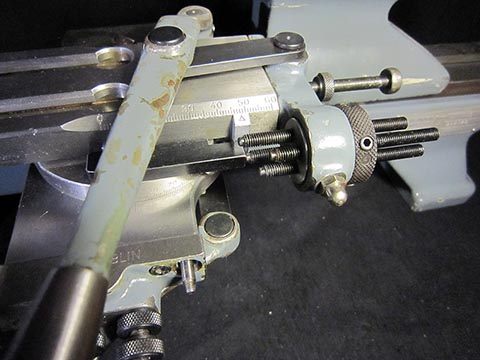

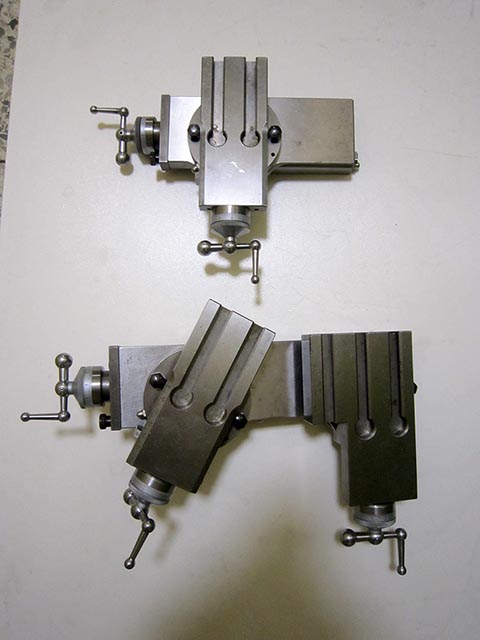

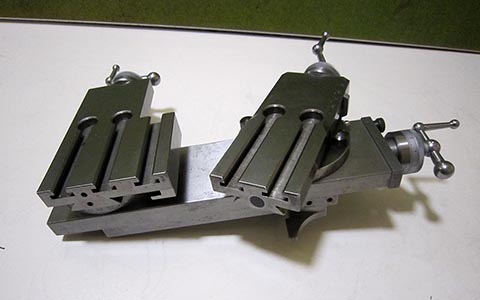

The machine is equipped with a belt tensioner for milling operations using the vertical and cross slides. For tool clamping, I use a quick-change tool holder of the “Tripan” type. For manual tool movement, a hand rest is used, which can be mounted and secured on the lathe bed in any desired position.

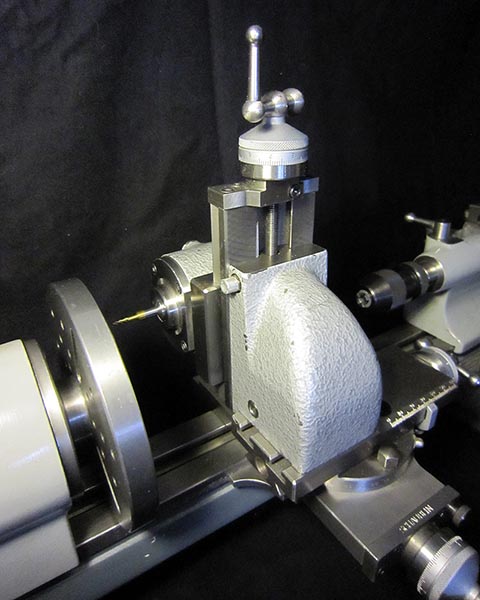

An indispensable tool in the manufacture of gears or screw balances is the dividing attachment, which divides components into precise circular segments.

To turn recesses for gears in plates, a faceplate is required — a disc-shaped tool with holes that is mounted on the spindle of the metalworking machine. The workpiece is secured with screws or clamping devices under a centering microscope.

Other important accessories include three-jaw, four-jaw, and six-jaw chucks. W12 collets in various sizes enable faster and more precise work. They fit both the headstock spindle and the tailstock spindle.

Another advantage of Schaublin 70 watchmaker accessories is that they are also compatible with machines from other manufacturers (Asiera, Hauser).